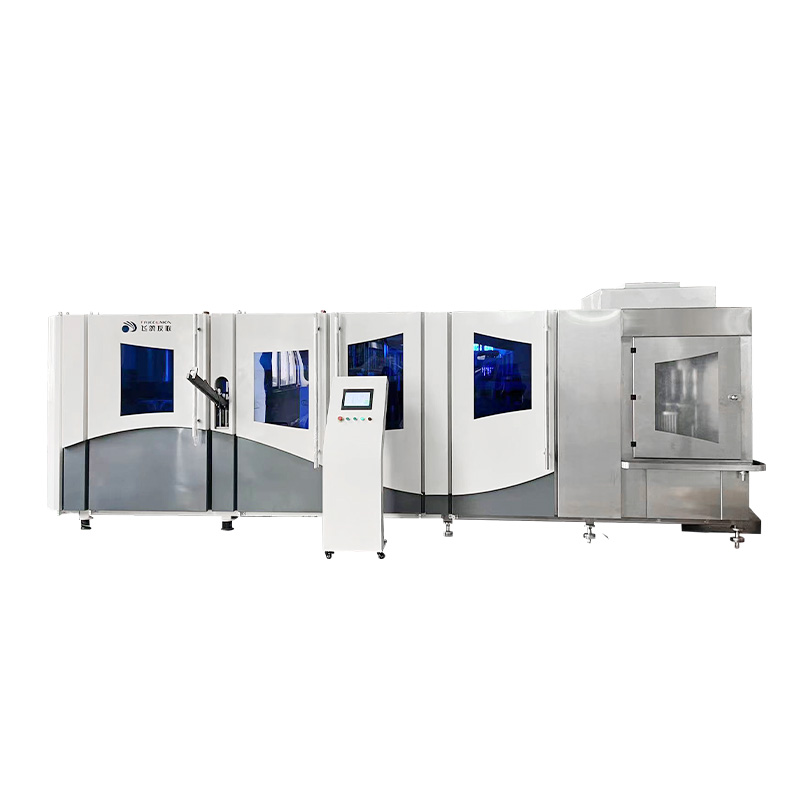

New Technology Mini Linear Blow Bottle Filling and Capping Integrated Machine

Small linear blow bottle filling and capping integrated machine

Stable, high-speed, energy-saving

The speed of this series of models is positioned at 10000-20000 bottles per hour

Suitable for small batch and multi specification customized water and other needs;

This series of models is independently developed and has independent intellectual property rights,

13 national patents have been obtained, including 5 national invention patents

Jiangsu Feige Youlian Machinery Co., Ltd. specializes in mini linear blow irrigation and rotation, saving you factory area

As CGX6-16-8, 10000 bottles per hour (using 500ml bottles as an example)

The machine is only 7 meters long and 1.6 meters wide.

Faygo Union CGX Series technical parameters

| MODEL | CGX6-16-8 | CGXX6-18-8 | CGXX8-24-10 | |

| Number of cavities (pieces) | 6 | 6 | 8 | |

| Canned valves (pieces) | 16 | 18 | 24 | |

| Spinning head (piece) | 8 | 8 | 10 | |

| Bottle specifications | Maximum volume of bottle (ml) | 2000 | 2000 | 750 |

| Maximum height of bottle (mm) | 328 | 328 | 300 | |

| Maximum diameter of bottle (mm) | 105 | 105 | 75 | |

| Bottle preform specifications | Bottle mouth inner diameter size (mm) | 20-25 | 20-25 | 20-25 |

| Maximum length of bottle preform (mm) | 150 | 150 | 140 | |

| Production (bottle/hour) (17g 500mL water bottle) | 10,000-11,000 | 12,000-13,000 | 15,000-16,000 | |

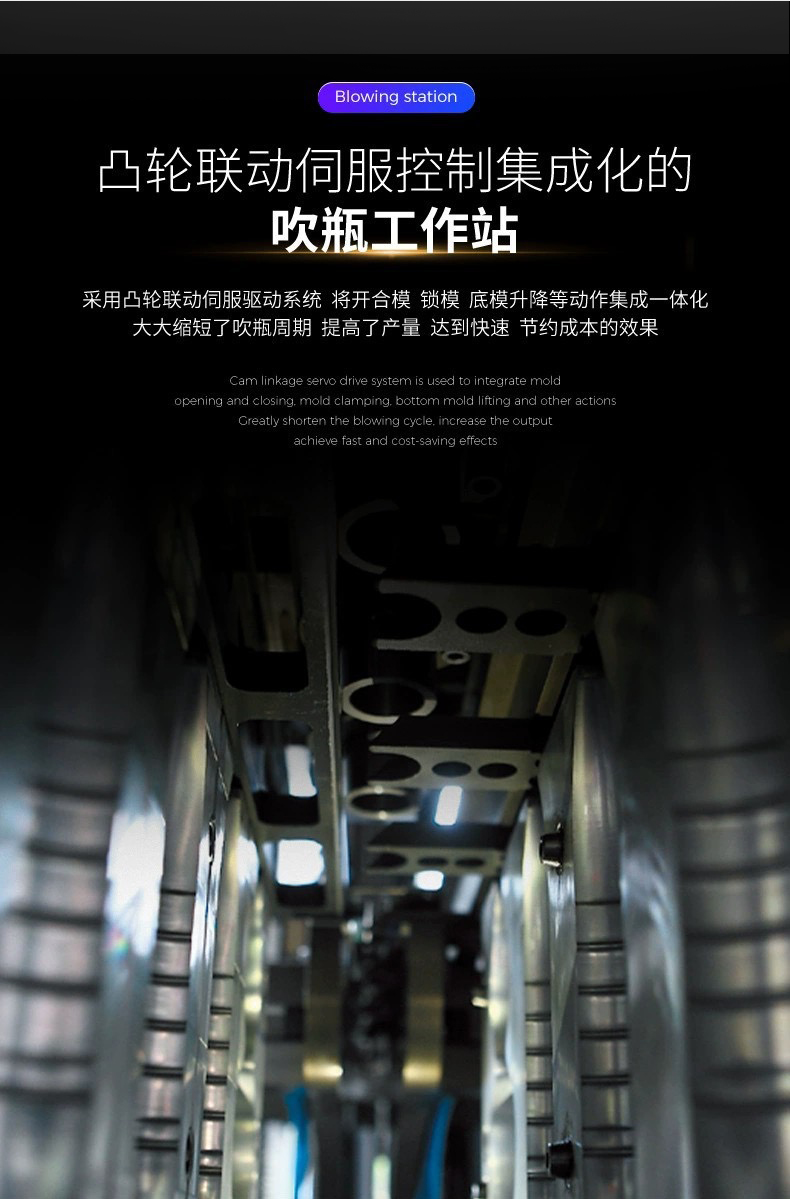

Integrated cam linkage servo control

Blowing bottle workstation

cam linkage servo drive system is used to integrate mold

opening and closing, mold clamping, bottom mold lifting and other actions

Greatly shorten the blowing cycle, increase the output

achieve fast and cost-saving effects

Heating system with small pitch

The heating head is arranged with a small pitch of38.lmm

which saves more than 3096 energy than the traditional heating furnace thus achieving the cost-saving

effect. The blowing system and the waste heat exhaust system are set up to

basically ensure the constant temperature of the blowing area

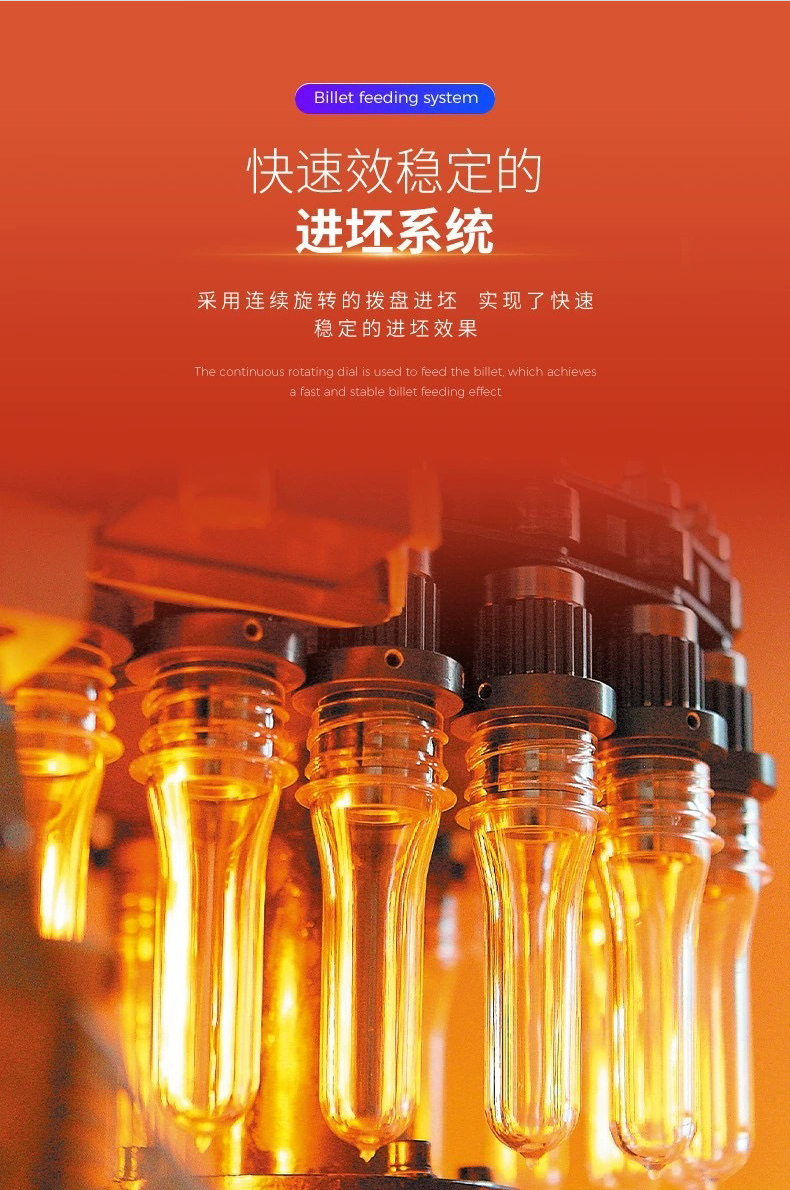

Billet feeding system

The continuous rotating dial is used to feed the billet. which achieves

a fast and stable billet feeding effect

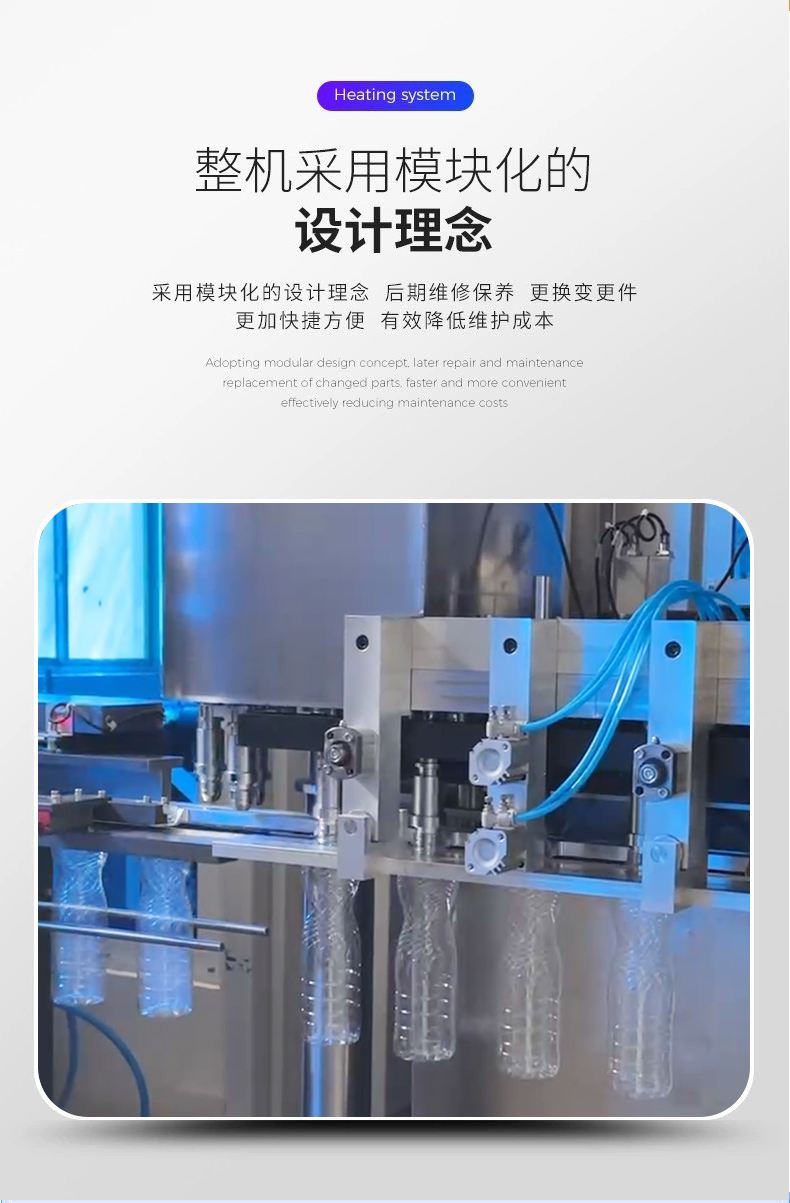

Heating system

Adopting modular design concept.

later repair and maintenancereplacement of changed parts

faster and more conwenienteffectively reducing maintenance costs

If the equipment fails due to the quality of the machine during one year, we will provide replacement and the repair Free of Charge. after One Year customer must pay for Spare Parts, we will provide long-term technical assistance.

Workers must operate the machines according to the design of the machine. Faygo Machinery will not be responsible for accidents which are caused by improper operation of workers.

FAYGO UNION GROUP has 3 branch factories. One is FAYGOBLOW which design and make blow molding machine for PET, PE etc. FAYGOBLOW has 5 patents of invention, and 8 patents utility models. FAYGO PET blow molding machine is one of fastest and most energy-efficient design in the world. Second factory is FAYGOPLAST, which make plastic extrusion machinery, including plastic pipe extruding line, plastic profile extruding line. Especially FAYGOPLAST can supply high speed up to 40 m/min PE,PPR pipe line. Third factory is FAYGO RECYCLING, which research new technology in plastic bottle ,film recycling processing and pelletizing. Now FAYGO RECYCLING can make up to 4000kg/hr. PET bottle washing line, and 2000kg/hr plastic film washing line.

Our factory is located in Zhangjiagang city, covers an area of 26,650 square meters. It only takes around two hours driving from SHANGHAI international airport. Welcome to visit our factory, and hope to cooperate with you in the near future.

Q:Are you machinery factory or trading company?

A:We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q:Installation and stuff training available from you?

A:Yes, our engineers will guide machine installation and train your workers.

Q:How can we visit your company and machines?

A:We are located in Zhangjiagang City which is about 2.5 hours nearby Shanghai Airport.If customer want to visit our factory,we will pick up you at the airport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Q:How long is the warranty?

A:1 year

Q:How long is the delivery time?

A:Under normal conditions, products are delivered within 45 working days.

Q:How can I know the stauts of my order?

A:We will send you photos and videos of your order at different satge in time and keep you informed of the latest information.

| |||

| PET blow molding machine | bottle water filing machine | air compressor | Injection blow molding machine |

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier