Welcome to TradeChina

High-Speed 3-in-1 Rotary Blowing, Filling & Capping Machine for Milk & Beverages

FOB Reference Price

Purchase quantity ()

Minimum order quantity

Payment

Jiangsu Faygo Union Machinery Co., Ltd.

China - Suzhou

Manufacturing and trade

Trade Capacity

Export Percentage

70-90%

Nearest Port

Shanghai,Ningbo

Accepted Delivery Terms

FOB,CIF,EXW

Employees

201-300 people

Accepted Payment Currency

USD,EUR,CNY

Average Lead Time

45 Day(s)

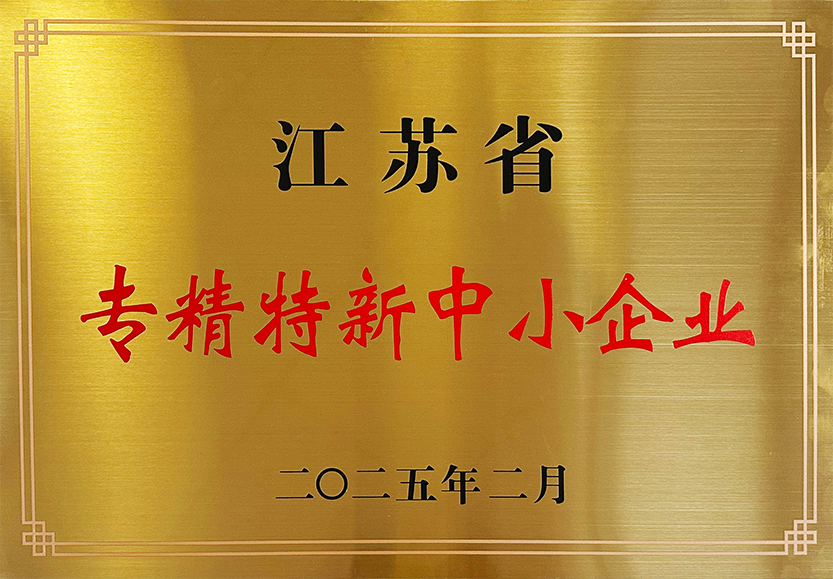

Certifications

Product Specifications

--Product Description

Products Description

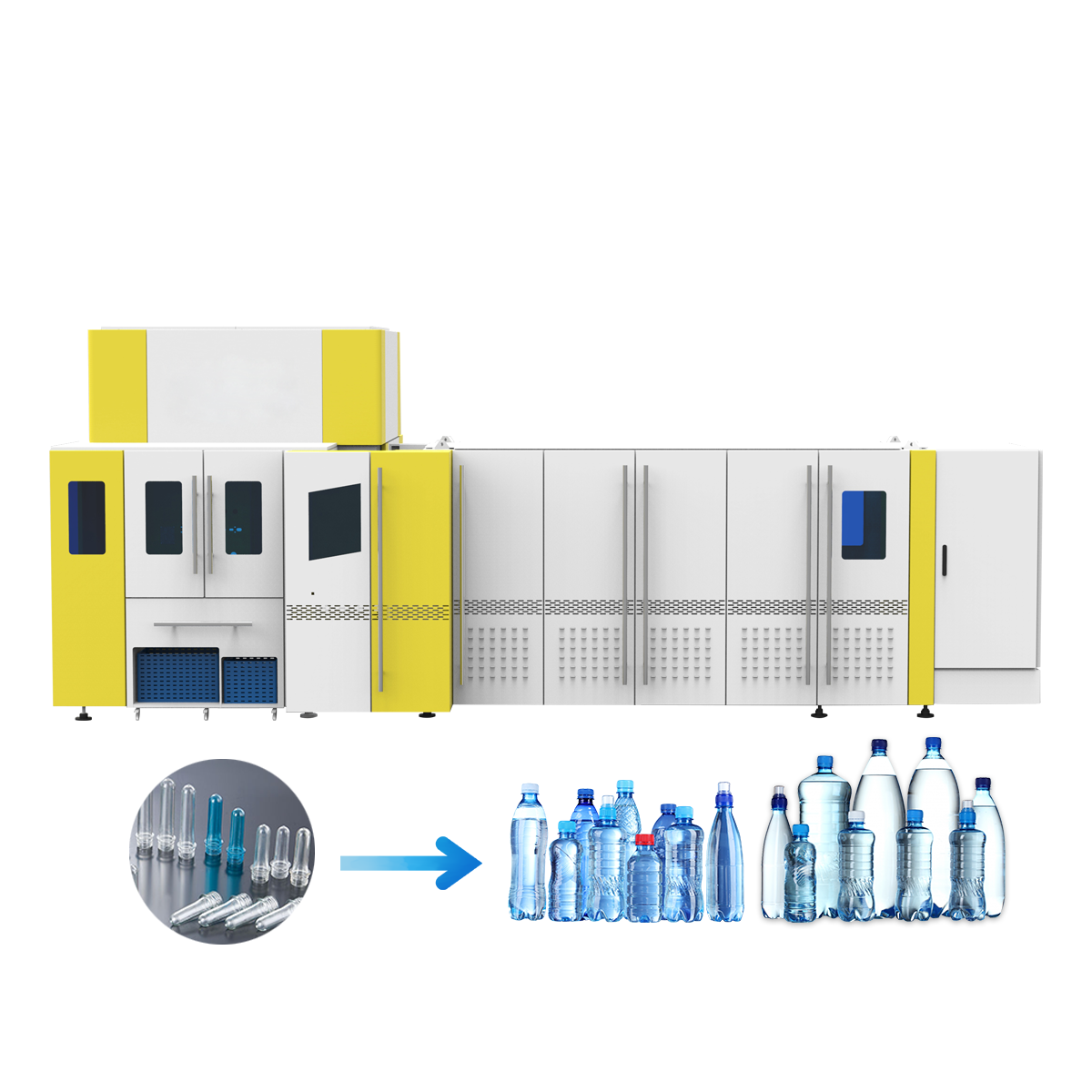

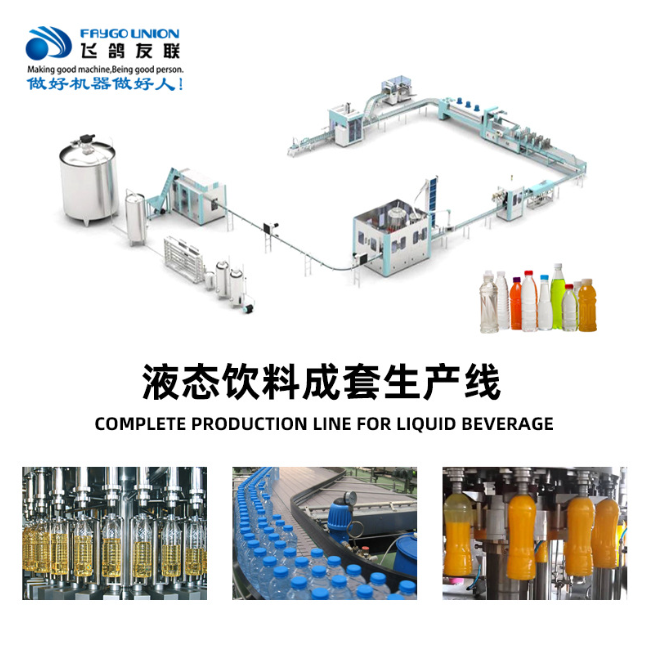

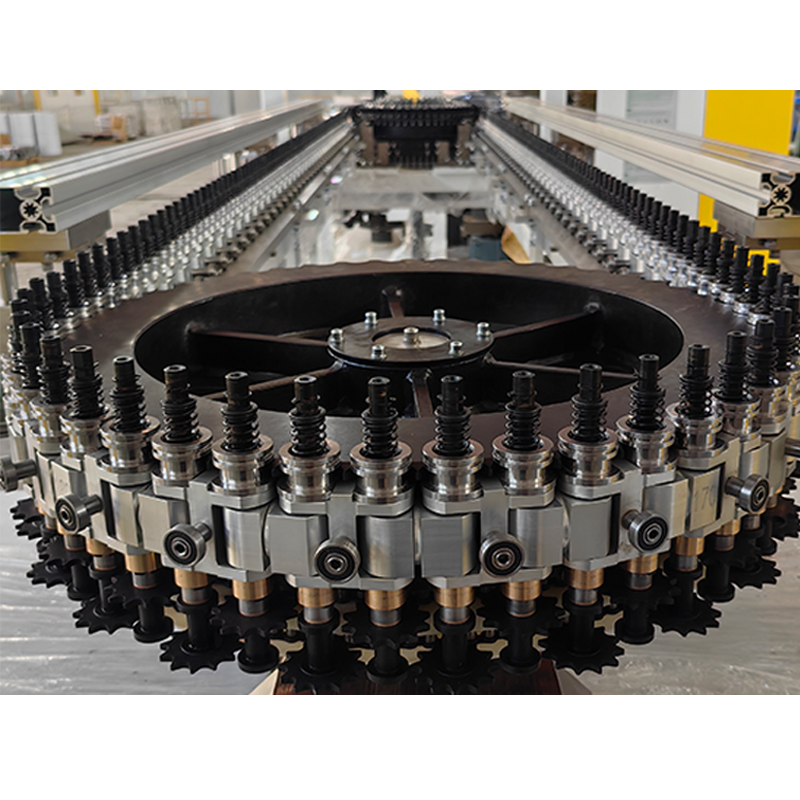

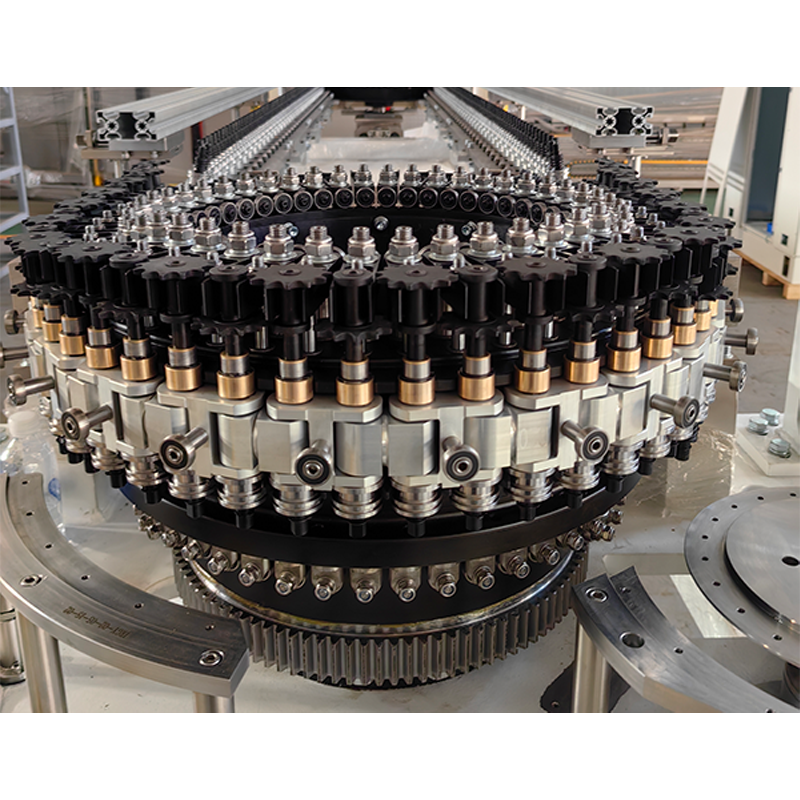

Rotary bottle blowing, filling and capping machine

The rotary bottle blowing, filling and capping machine integrates bottle blowing, filling and capping to achieve highly automated production, and is suitable for beverage, cosmetics and other industries. The equipment has a large output and can meet the needs of mass production. At the same time, it has an energy-saving design, which effectively reduces energy consumption and production costs, ensures an efficient and stable production process, and improves product quality and consistency.

Product introduction

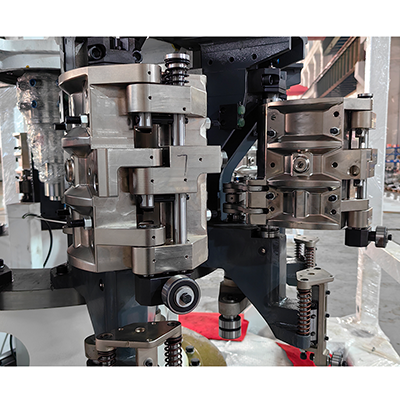

Product Details

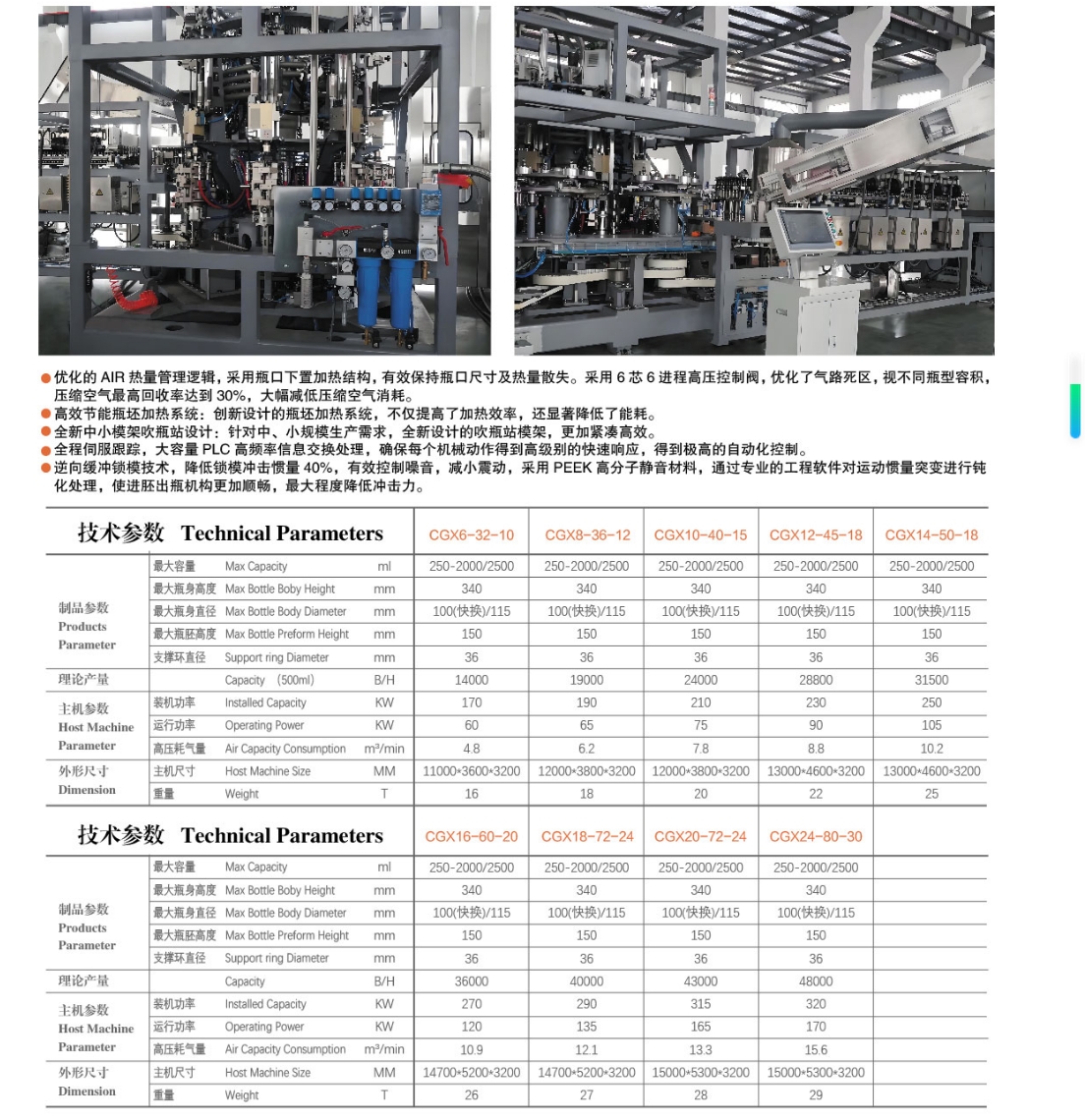

The optimized AIR heat management logic adopts the bottle mouth bottom heating structure to effectively maintain the bottle mouth size and heat dissipation. The 6-core 6-process high-pressure control valve is adopted to optimize the dead zone of the air path, depending on the volume of different bottle types.

The maximum recovery rate of compressed air reaches 30%, which greatly reduces the consumption of compressed air.

High-efficiency and energy-saving bottle heating system: The innovatively designed bottle heating system not only improves the heating efficiency, but also significantly reduces energy consumption.

● New small and medium-sized mold frame blowing station design: Aiming at the needs of medium and small-scale production, the newly designed blowing station mold is more compact and efficient.

● Full-process servo tracking, large-capacity PLC high-frequency information exchange processing, ensure that each mechanical action gets a high-level rapid response and extremely high automation control.

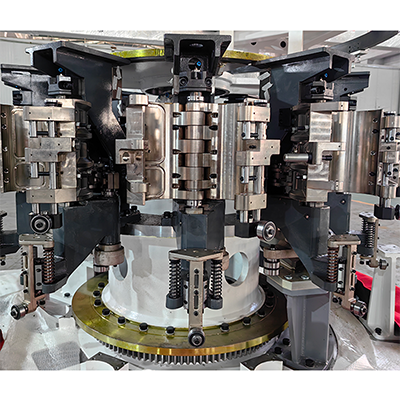

● Reverse buffer clamping technology reduces the mold impact inertia by 40%, effectively controls noise, reduces vibration, adopts PEEK polymer silent material, and uses professional engineering software to passivate the sudden change of motion inertia, making the embryo feeding and bottle discharging mechanism smoother and minimizing the impact force.

Machine Picture

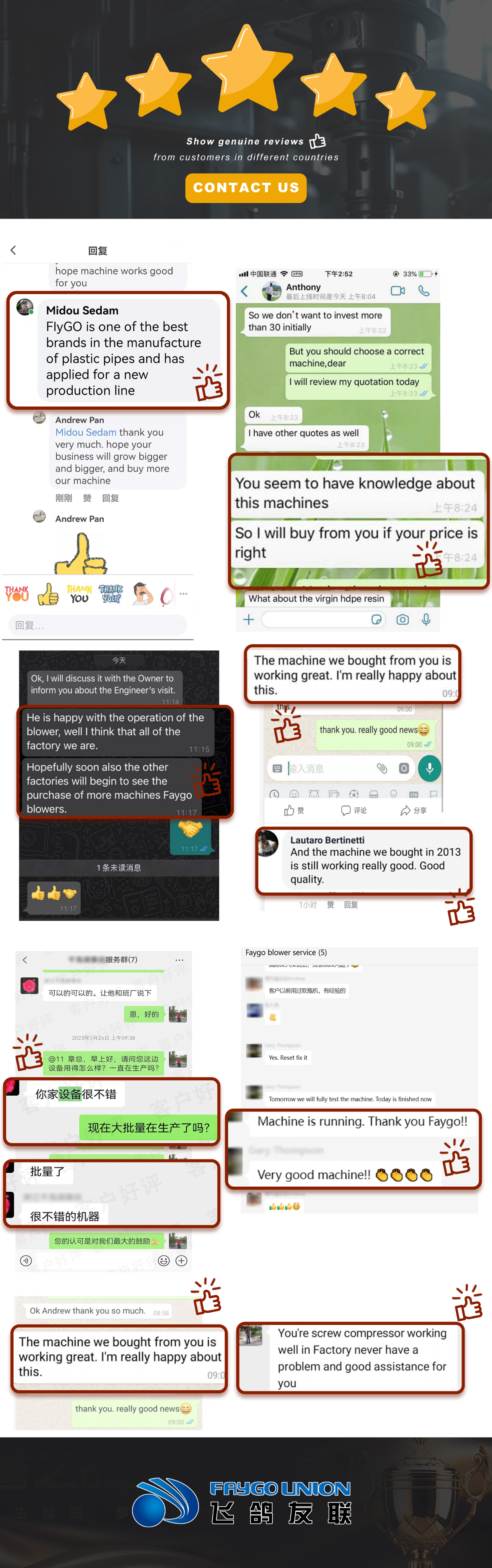

Why Choose us

Our Factory

Packing

FAQ

Q: What is a plastic extruder?

A: A plastic extruder is a device used to heat, melt and mold plastic raw materials into continuous profiles through a mold. It is widely used in the production of pipes, plates, films and other products.

Q: What is the working principle of a plastic extruder?

A: It feeds plastic particles into a heating barrel through the rotation of the screw. The plastic melts at high temperature, then is extruded through a mold and then cooled to form the final product.

Q: What types of plastic extruders are there?

A: They are mainly divided into single-screw extruders, twin-screw extruders and multi-screw extruders. Different types are selected according to production needs.

Q: How to maintain a plastic extruder?

A: Clean the screw and mold regularly, check the heating system and transmission parts, and ensure that the equipment is well lubricated to extend its service life.

Q: What materials can a plastic extruder handle?

A: It can handle a variety of thermoplastics such as PE, PP, PVC, ABS, etc., depending on the equipment configuration and mold design.

No desirable products?

How to start your business

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier

Supplier's popular products

High Speed PET Blow Molding Machine

$ 75,000

>=1 Set(s)

Faygo Union Automatic Plastic Blowing Machine Water Making 1.5L Plastic Bottle Blowing Machine

$ 75,000 ~ $ 90,000

>=1 Set(s)

Semi Automatic Bottle Blowing Machine Complete Bottle Water Production Line

$ 2,200 ~ $ 2,500

>=1 Piece(s)

3D Pprinter Filament Extruder Machine Lab Single Screw Plastic Extrusion Line with PLC Control

$ 8,500 ~ $ 30,000

>=1 Set(s)

SJSZ-80-156 Twin Screw Extruder Machine for Tpu Double Screw Pvc Pipe Extruder

$ 29,500 ~ $ 31,500

>=1 Piece(s)

High Speed Automatic PET Bottle Blow Molding Machine / Blowing Moulding Machine Price

$ 70,000 ~ $ 75,000

>=1 Set(s)

90~400mm Class 500 PVC-O Pipe Production Line

$ 250,000

>=1 Set(s)

Pe Ps Granulator Foam Product Granulating Plastic Waste Rubber Tyre Recycle Machine

$ 29,000 ~ $ 30,000

>=1 Set(s)

Faygoplast Double Head Aluminium Plastic Composite 3 Layers High Quality Polythene Foam PPR Pipe Machine

$ 30,000

>=1 Set(s)

High Quality Parallel Twin Screw PVC UPVC CPVC Electric Plastic Pipe Machine Line

$ 25,000

>=1 Set(s)

FAYGO UNION Acrylonitrile Butadiene Styrene ABS Plastic Dwv Pipe Line Making Machine Full Automatic

$ 35,000

>=1 Piece(s)

Faygo Union 2024 Twin Screw UPVC PVC Pipe Plastic Extruder Machine

$ 25,000

>=1 Set(s)