1.HDPE pipe manufacturing line with the help of polymer forming and processing technology, heated molten material is extruded from the die through the main extruder and then formed into a round tube by vacuum sizing, then the cooled tube is fully formed and passed through the main extruder and extruded from the die through the main extruder.

2.The square tube is guided to the sewing machine and the hot melt adhesive is produced by a smaller size extruder. A spiral winding motion of the extruded square tube can be produced by forming rolls on the forming machine and forming an angle with the axis of the formed tube.

3.The die head layer of the molten adhesive extruder is extruded through the nozzle into the gap between two adjacent square tubes as the die head layer is extruded through the nozzle into the sides of the two adjacent square tubes.

4.The forming machine has an attached spray system. Cooled and placed in a dry place. Curing design. In this way, the hollow square tubes are wound continuously along the p-angle direction, bonded, cooled, cured and advanced to form the inner diameter of the HDPE large diameter hollow wound tubes.

Welcome to TradeChina

HDPE Pipe Extrusion Line / HDPE Pipe Making Machine

FOB Reference Price

Purchase quantity ()

Minimum order quantity

Payment

Jiangsu Faygo Union Machinery Co., Ltd.

China - Suzhou

Manufacturing and trade

Trade Capacity

Export Percentage

70-90%

Nearest Port

Shanghai,Ningbo

Accepted Delivery Terms

FOB,CIF,EXW

Employees

201-300 people

Accepted Payment Currency

USD,EUR,CNY

Average Lead Time

45 Day(s)

Certifications

Product Specifications

--Product Description

Product Description

What is HDPE pipe extruder machine used for?

Application field of HDPE extruder

1. Urban water supply system. Large-diameter HDPE pipes are healthy and non-toxic and are more suitable for the use of urban water supply and drainage mains and branch pipes.

2. Replace cement pipes, iron pipes, and steel pipes. It is suitable for renovation projects and does not require large-scale

excavation. HDPE pipes can be widely used in the renovation of pipe networks in old urban areas.

3. Industrial raw material transmission pipeline. Chemical, chemical fiber, food, forestry, pharmaceutical, light industry, paper, metallurgy, and other industrial raw material conveying pipes.

4. Landscape water supply network. Since the greening project requires a large number of water supply pipes, HDPE pipes are the best choice for their toughness and low cost.

5. Sewage discharge pipeline. HDPE pipes have unique corrosion resistance and can be used in industrial wastewater and sewage discharge pipes.

6. Ore and mud transfer. HDPE pipe has high-stress resistance and wear resistance, and can be widely used in conveying ore, coal ash, and river mud.

7. Agricultural irrigation pipes. HDPE pipe has the advantages of large flow and good impact resistance and is an ideal tool for agricultural irrigation.

1. Urban water supply system. Large-diameter HDPE pipes are healthy and non-toxic and are more suitable for the use of urban water supply and drainage mains and branch pipes.

2. Replace cement pipes, iron pipes, and steel pipes. It is suitable for renovation projects and does not require large-scale

excavation. HDPE pipes can be widely used in the renovation of pipe networks in old urban areas.

3. Industrial raw material transmission pipeline. Chemical, chemical fiber, food, forestry, pharmaceutical, light industry, paper, metallurgy, and other industrial raw material conveying pipes.

4. Landscape water supply network. Since the greening project requires a large number of water supply pipes, HDPE pipes are the best choice for their toughness and low cost.

5. Sewage discharge pipeline. HDPE pipes have unique corrosion resistance and can be used in industrial wastewater and sewage discharge pipes.

6. Ore and mud transfer. HDPE pipe has high-stress resistance and wear resistance, and can be widely used in conveying ore, coal ash, and river mud.

7. Agricultural irrigation pipes. HDPE pipe has the advantages of large flow and good impact resistance and is an ideal tool for agricultural irrigation.

Composition of HDPE pipe extrusion line

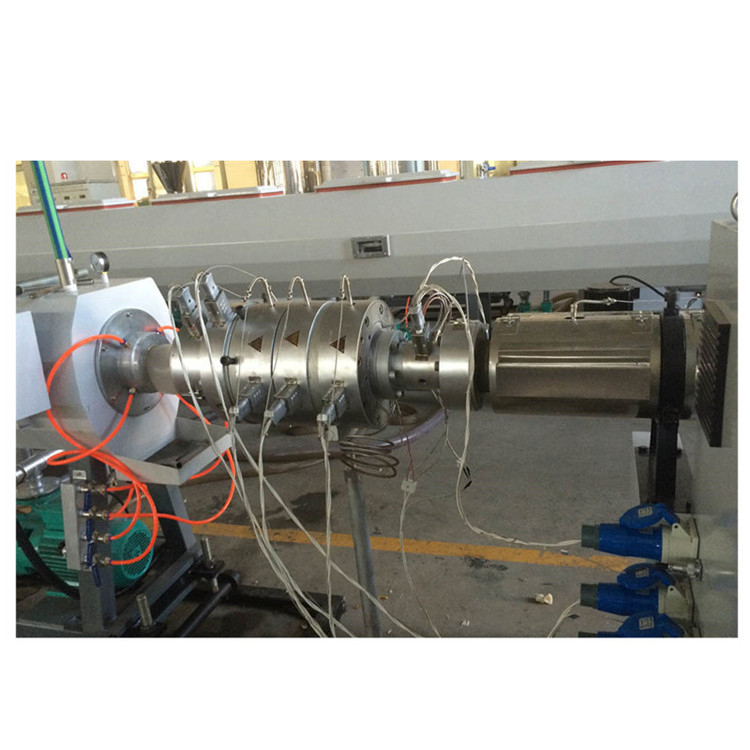

1. The HDPE pipe extruder adopts a high-efficiency screw barrel, and the gearbox is a hard-toothed gearbox with a self-lubricating system. The motor adopts Siemens standard motor, and the speed is controlled by an ABB frequency converter. The control system adopts Siemens PLC control or button control.

2. The PE pipeline consists of the following: material feeder + single screw extruder + tube mold + vacuum calibration box + spray cooling box x 2 sets + three crawler tractors + dust-free cutter + stacker.

3. The box body of the vacuum calibration box adopts two chamber structures: vacuum calibration and cooling parts. Both the vacuum box and the spray cooling box are made of 304# stainless steel. An excellent vacuum system ensures the precise size of pipes; spray cooling will improve cooling efficiency; an automatic water temperature control system makes the machine more intelligent.

4. The tractor of this pipeline will be crawler-type. Using the gauge code, it can calculate the pipe length during production.

The cutting system adopts a dust-free cutting machine and PLC control system.

2. The PE pipeline consists of the following: material feeder + single screw extruder + tube mold + vacuum calibration box + spray cooling box x 2 sets + three crawler tractors + dust-free cutter + stacker.

3. The box body of the vacuum calibration box adopts two chamber structures: vacuum calibration and cooling parts. Both the vacuum box and the spray cooling box are made of 304# stainless steel. An excellent vacuum system ensures the precise size of pipes; spray cooling will improve cooling efficiency; an automatic water temperature control system makes the machine more intelligent.

4. The tractor of this pipeline will be crawler-type. Using the gauge code, it can calculate the pipe length during production.

The cutting system adopts a dust-free cutting machine and PLC control system.

process of pipe producting

HIGH SPEED !!

Advantages of HDPE pipe machinery

1. The water supply pipes are non-toxic. HDPE material is non-toxic and tasteless, it is a green building material, and has passed strict health tests, effectively improving the water quality. Make sure the quality meets your needs.

2. Low flow resistance. The inner wall is smooth and the pipeline transportation is convenient. Under the same conditions, the transportation capacity of HDPE pipeline can be increased by 30% because its roughness is much smaller than that of steel pipe and glass steel pipe.

3. No leakage. HDPE pipes are connected by hot melt butt joint, hot melt socket connection and electrofusion connection, which means that the strength of the connection point is higher than that of the pipe itself.

4. Excellent flexibility. Small diameter HDPE pipes can be rolled into coils. At the same time, large-diameter products can also be slightly bent, which is more convenient on the construction site.

5. Good scratch resistance. The wear resistance of HDPE pipe is 4 times that of steel pipe, which means that the service life of HDPE pipe is longer and the economy is better.

6. Convenient construction. PE pipe can be installed in various trenchless ways, which is convenient for construction and

installation.

7. Long life. Predicted 50-year service life at rated temperature and pressure design.

8. Reduce operating and maintenance costs. High-density polyethylene pipes are not only convenient for transportation and installation, but also greatly reduce the labor intensity of workers and improve work efficiency.

2. Low flow resistance. The inner wall is smooth and the pipeline transportation is convenient. Under the same conditions, the transportation capacity of HDPE pipeline can be increased by 30% because its roughness is much smaller than that of steel pipe and glass steel pipe.

3. No leakage. HDPE pipes are connected by hot melt butt joint, hot melt socket connection and electrofusion connection, which means that the strength of the connection point is higher than that of the pipe itself.

4. Excellent flexibility. Small diameter HDPE pipes can be rolled into coils. At the same time, large-diameter products can also be slightly bent, which is more convenient on the construction site.

5. Good scratch resistance. The wear resistance of HDPE pipe is 4 times that of steel pipe, which means that the service life of HDPE pipe is longer and the economy is better.

6. Convenient construction. PE pipe can be installed in various trenchless ways, which is convenient for construction and

installation.

7. Long life. Predicted 50-year service life at rated temperature and pressure design.

8. Reduce operating and maintenance costs. High-density polyethylene pipes are not only convenient for transportation and installation, but also greatly reduce the labor intensity of workers and improve work efficiency.

Specification

Description of goods | Quantity |

Material Charger | 1pc |

Single Screw Extruder | 1pc |

Mold | 1pc |

Vacuum Calibration Tank | 1pc |

Haul-off and Cutting Machine Unit | 1pc |

Stacker | 1pc |

Professional Certificate

Company Profile

Jiangsu Faygo Union Machinery Co.,ltd is a Group company in Industrial world. It is professional manufacturer of complete plastic pipe/profile extrusion line, plastic recycling &pelletizing line, WPC composite line.

Jiangsu Faygo Union Machinery Co., Ltd. has a more than 10,000-square-meter modern production workshop. We have excellent processing equipment, and have passed European CE and international SGS certifications. After years of technology accumulation and product innovation, our company has had customers from at home and abroad and won a good reputation in the market.

"Business integrity, quality first" is our principle. Our company is equipped with a professional team of quality control and after-sales service staff members to keep track of each order scientifically so as to provide high-speed services for customers.

We insist on the tenet of "professional development, improving our skills". Main products of our company are plastic pipe extrusion lines, plastic profile extrusion lines and plastic recycling equipment. We have won high praises from general customers.

Faygoplast looks forward to cooperating with you! We will strive to produce more quality products!

Packing & Delivery

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2010,sell to Domestic Market(22.00%),Africa(20.00%),Western Europe(13.00%),South America(10.00%),Southeast Asia(10.00%),North America(5.00%),Eastern Europe(5.00%),Mid East(5.00%),Southern Europe(5.00%),South Asia(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Pipe Making Machine,Blow Molding Machine,Plastic profile making Machine,Plastic Recycling Machine,Air Compressor

4. why should you buy from us not from other suppliers?

specialized in PET bottle blow machine, plastic pipe extrusion line and plastic sheet & board production line workshop area:20000 squire meters provide quality machne, and perfer long term comperature, company idea: make good machine, being good person

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,HKD,GBP,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

We are based in Jiangsu, China, start from 2010,sell to Domestic Market(22.00%),Africa(20.00%),Western Europe(13.00%),South America(10.00%),Southeast Asia(10.00%),North America(5.00%),Eastern Europe(5.00%),Mid East(5.00%),Southern Europe(5.00%),South Asia(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Pipe Making Machine,Blow Molding Machine,Plastic profile making Machine,Plastic Recycling Machine,Air Compressor

4. why should you buy from us not from other suppliers?

specialized in PET bottle blow machine, plastic pipe extrusion line and plastic sheet & board production line workshop area:20000 squire meters provide quality machne, and perfer long term comperature, company idea: make good machine, being good person

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,HKD,GBP,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

No desirable products?

How to start your business

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier

Supplier's popular products

High Speed PET Blow Molding Machine

$ 75,000

>=1 Set(s)

Faygo Union Automatic Plastic Blowing Machine Water Making 1.5L Plastic Bottle Blowing Machine

$ 75,000 ~ $ 90,000

>=1 Set(s)

Semi Automatic Bottle Blowing Machine Complete Bottle Water Production Line

$ 2,200 ~ $ 2,500

>=1 Piece(s)

3D Pprinter Filament Extruder Machine Lab Single Screw Plastic Extrusion Line with PLC Control

$ 8,500 ~ $ 30,000

>=1 Set(s)

SJSZ-80-156 Twin Screw Extruder Machine for Tpu Double Screw Pvc Pipe Extruder

$ 29,500 ~ $ 31,500

>=1 Piece(s)

High Speed Automatic PET Bottle Blow Molding Machine / Blowing Moulding Machine Price

$ 70,000 ~ $ 75,000

>=1 Set(s)

90~400mm Class 500 PVC-O Pipe Production Line

$ 250,000

>=1 Set(s)

Pe Ps Granulator Foam Product Granulating Plastic Waste Rubber Tyre Recycle Machine

$ 29,000 ~ $ 30,000

>=1 Set(s)

Faygoplast Double Head Aluminium Plastic Composite 3 Layers High Quality Polythene Foam PPR Pipe Machine

$ 30,000

>=1 Set(s)

High Quality Parallel Twin Screw PVC UPVC CPVC Electric Plastic Pipe Machine Line

$ 25,000

>=1 Set(s)

FAYGO UNION Acrylonitrile Butadiene Styrene ABS Plastic Dwv Pipe Line Making Machine Full Automatic

$ 35,000

>=1 Piece(s)

Faygo Union 2024 Twin Screw UPVC PVC Pipe Plastic Extruder Machine

$ 25,000

>=1 Set(s)