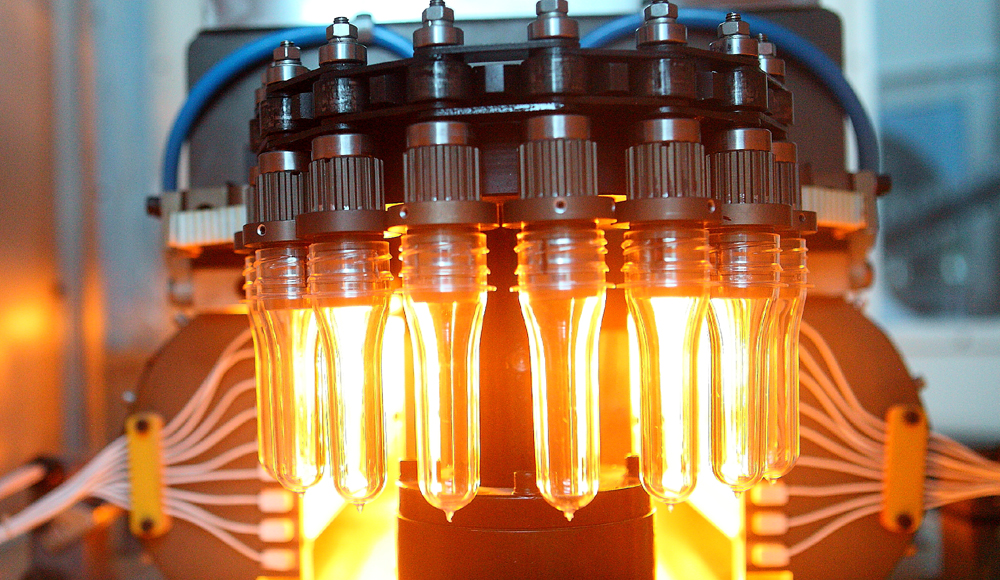

During the blowing process,if the bottle bursts,bad bottles can be automatically removed. This prevents the bad bottles from

entering the filling machine.

Welcome to TradeChina

Faygoplast High Quality with Long Service Life Mineral Water Automatic Bottle Blow Moulding Machine

FOB Reference Price

Purchase quantity ()

Minimum order quantity

Payment

Jiangsu Faygo Union Machinery Co., Ltd.

China - Suzhou

Manufacturing and trade

Trade Capacity

Export Percentage

70-90%

Nearest Port

Shanghai,Ningbo

Accepted Delivery Terms

FOB,CIF,EXW

Employees

201-300 people

Accepted Payment Currency

USD,EUR,CNY

Average Lead Time

45 Day(s)

Certifications

Product Specifications

--Product Description

Product Description

Specification

Model | FG4 | ||||

Mold Number(piece) | 4 | ||||

Max Capacity(BPH) | 6500-8000 | ||||

bottle specification | Max Volume(ml) | 2000 | |||

Max Height(mm) | 328 | ||||

Round bottle Max Diameter(mm) | 105 | ||||

Square bottle max diagonal(mm) | 105 | ||||

preform specification | Suitable inner bottle neck(mm) | 20-25 | |||

Max preform length(mm) | 150 | ||||

Electricity | Total installation power(kw) | 51 | |||

Heating oven total power(kw) | 46 | ||||

Heating oven real power(kw) | 22 | ||||

Voltage/frequency(V/Hz) | 380(50Hz) | ||||

Allowed voltage fluctuation range | ±10% | ||||

Compressed air | pressure(bar) | 30 | |||

Air consumption(m³/min) | 4 | ||||

Cooling water | Mold water | Pressure(bar) | 4-6 | ||

Temperature regulation range(℃) | 6-13 | ||||

Flow rate(L/min) | 45 | ||||

Oven water | Pressure(bar) | 4-6 | |||

Temperature regulation range(℃) | 6-13 | ||||

Flow rate(L/min) | 22 | ||||

Machine specification | Machine dimension(m)(L*W*H) | 3.8*1.3*2.3 | |||

Machine weight(Kg) | 3500 | ||||

Our Advantages

Exploded bottles rejection unit

After the bottle blowing, high pressure air can be recycled and used again for the pre-blowing

and machine physical movement.

and machine physical movement.

Thermal sensing unit detects temperature in oven and temperature of heated performs.When the temperature does not reach the set blowing temperature,blowing workstation will alarm, not blown.

Packing & Delivery

Wooden case

Company Profile

Jiangsu Faygo Union Machinery Co.,ltd is a Group company in Industrial world. It is professional manufacturer of complete plastic pipe/profile extrusion line, plastic recycling &pelletizing line, WPC composite line.

Jiangsu Faygo Union Machinery Co., Ltd. has a more than 10,000-square-meter modern production workshop. We have excellent processing equipment, and have passed European CE and international SGS certifications. After years of technology accumulation and product innovation, our company has had customers from at home and abroad and won a good reputation in the market.

"Business integrity, quality first" is our principle. Our company is equipped with a professional team of quality control and after-sales service staff members to keep track of each order scientifically so as to provide high-speed services for customers.

We insist on the tenet of "professional development, improving our skills". Main products of our company are plastic pipe extrusion lines, plastic profile extrusion lines and plastic recycling equipment. We have won high praises from general customers.

Faygoplast looks forward to cooperating with you! We will strive to produce more quality products!

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2010,sell to Domestic Market(00.00%),Africa(00.00%),Western Europe(00.00%),South America(00.00%),Southeast Asia(00.00%),North America(00.00%),Eastern Europe(00.00%),Mid East(00.00%),Southern Europe(00.00%),South Asia(00.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Pipe Making Machine,Blow Molding Machine,Melt Blown Cloth Production Line,Injection Blow Molding Machine,Air Compressor

4. why should you buy from us not from other suppliers?

specialized in PET bottle blow machine, plastic pipe extrusion line and plastic sheet & board production line workshop area:20000 squire meters provide quality machne, and perfer long term comperature, company idea: make good machine, being good person

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,HKD,GBP,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

We are based in Jiangsu, China, start from 2010,sell to Domestic Market(00.00%),Africa(00.00%),Western Europe(00.00%),South America(00.00%),Southeast Asia(00.00%),North America(00.00%),Eastern Europe(00.00%),Mid East(00.00%),Southern Europe(00.00%),South Asia(00.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Pipe Making Machine,Blow Molding Machine,Melt Blown Cloth Production Line,Injection Blow Molding Machine,Air Compressor

4. why should you buy from us not from other suppliers?

specialized in PET bottle blow machine, plastic pipe extrusion line and plastic sheet & board production line workshop area:20000 squire meters provide quality machne, and perfer long term comperature, company idea: make good machine, being good person

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,HKD,GBP,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

No desirable products?

How to start your business

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier

Supplier's popular products

High Speed PET Blow Molding Machine

$ 75,000

>=1 Set(s)

Faygo Union Automatic Plastic Blowing Machine Water Making 1.5L Plastic Bottle Blowing Machine

$ 75,000 ~ $ 90,000

>=1 Set(s)

Semi Automatic Bottle Blowing Machine Complete Bottle Water Production Line

$ 2,200 ~ $ 2,500

>=1 Piece(s)

3D Pprinter Filament Extruder Machine Lab Single Screw Plastic Extrusion Line with PLC Control

$ 8,500 ~ $ 30,000

>=1 Set(s)

SJSZ-80-156 Twin Screw Extruder Machine for Tpu Double Screw Pvc Pipe Extruder

$ 29,500 ~ $ 31,500

>=1 Piece(s)

High Speed Automatic PET Bottle Blow Molding Machine / Blowing Moulding Machine Price

$ 70,000 ~ $ 75,000

>=1 Set(s)

90~400mm Class 500 PVC-O Pipe Production Line

$ 250,000

>=1 Set(s)

Pe Ps Granulator Foam Product Granulating Plastic Waste Rubber Tyre Recycle Machine

$ 29,000 ~ $ 30,000

>=1 Set(s)

Faygoplast Double Head Aluminium Plastic Composite 3 Layers High Quality Polythene Foam PPR Pipe Machine

$ 30,000

>=1 Set(s)

High Quality Parallel Twin Screw PVC UPVC CPVC Electric Plastic Pipe Machine Line

$ 25,000

>=1 Set(s)

FAYGO UNION Acrylonitrile Butadiene Styrene ABS Plastic Dwv Pipe Line Making Machine Full Automatic

$ 35,000

>=1 Piece(s)

Faygo Union 2024 Twin Screw UPVC PVC Pipe Plastic Extruder Machine

$ 25,000

>=1 Set(s)