Cpvc Conduit Electric Pipe Manufacturing Making Equipment Machine

20-63mm PVC Double Pipe Extrusion Machine Line

Features of our machine PVC Pipe Making Machine:

PVC electrical conduit pipe extrusion line is used to produce pvc electric conduit pipe with diamater from 16 to 63mm, which are flexible, bendable in the aspect of electric wire protecting.

Capacity: Conical twin-screw extruder, suitable for process PVC powder with high capacity

Diameter: Friend machinery succeed in designing and producing the biggest conical twin-screw extruder in the world.

Auxiliary machine closely meet customer specifications. Nice apperance, automatic control and stable running performance.

1 | SJSZ65/132 Conical Twin Srew Plastic Extruder | 1set |

2 | Mould | 1set |

3 | Vacuum Calibration Tank | 1set |

4 | Two caterpillars Hauling Machine – | 1set |

5 | Pipe Cutting Machine | 1set |

6 | Stacker | 1set |

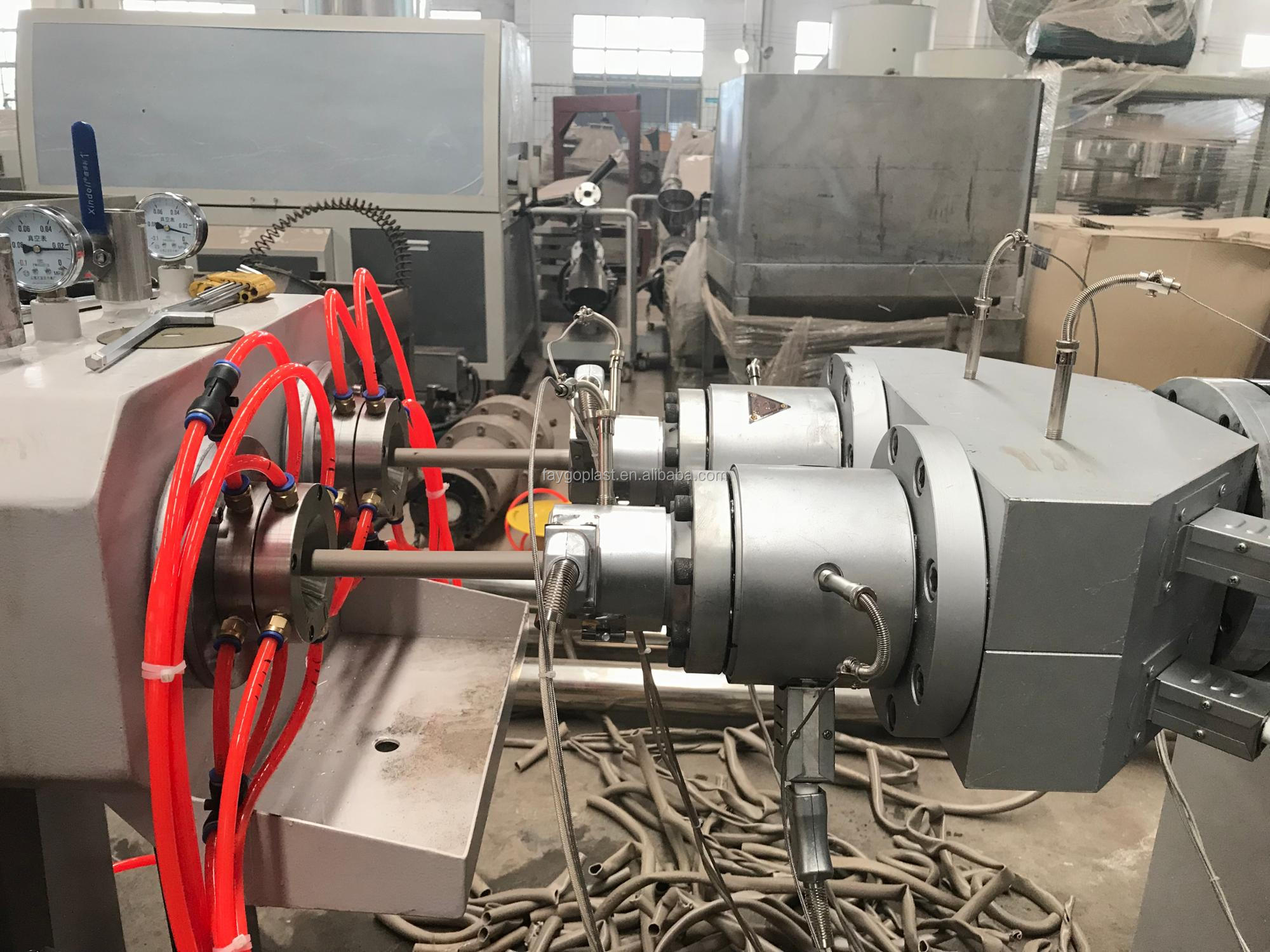

Machine Picture

1.The extruder and haul-off adopt imported AC frequency control device, vacuum pump and haul-off motors adopt high-quality brand.

2.The haul-off methods are two-claw, three-claw, four-claw, six-claw, eight-claw etc.

3.You may choose saw cutting type or planetary cutting type. It is additionally attached with the length counter and intensifying device.

4.The equipment is with the reliable performance and high production efficiency.

1. SJSZ65/132 Twin screw extruder machine:

Screw and Barrel: Design for CPVC material, Screw and Barrel Material 38CrMoAlA,Nitriding, Surface Chrome plate, Nitriding Layer Thickness:0.5~0.7mm, Surface Rigidity:800~900HV.

2. Pipe Mold

Extrusion mold material: 40Cr. Calibration mold material: Wearable tin bronze ZQSn5-2-5.

3. Vacuum calibration tank

Calibration Tank Length: 6m, Adopt 3mm thickness stainless steel board, Adopt 0.75KW Gearbox Speed Reducer Motor, Adjusting Distance equal to 800mm

4. Haul off and cutting machine

Haul-off Bracket Length 1200mm, Adopt Pneumatic gas cylinder,

Adopt 1.5kw*2sets ABB Inverter, Belt 80mm*2500mm.

5. Stacker

Stacker length 4m, 1.5mm stainless steel board,

Stacking by Gas cylinder, Adopt limited switch send out cutting signal.

Packing by film or wooden cases.

1.Your company is a trading company or a direct factory?

We are a direct factory located in Zhangjiagang City. Very close to Shanghai and Wuxi (airport and train provided). If you arrive in Shanghai or Wuxi, we can pick you up to visit our factory.

2.If we buy your machine, what is your guarantee or guarantee of quality?

We provide you with high-quality machines with 1-year warranty and lifetime technical support.

3.How to ensure the safety of your funds and deliver on time?

1/Through Alibaba's letter guarantee service, it will ensure on-time delivery and the quality of the equipment to be purchased.

2/Through the letter of credit, you can easily lock the delivery time.

3/After visiting the factory, you can ensure the authenticity of our bank account.

4.Check how ECENG MACHINE ensures quality!

1/In order to ensure the accuracy of each part, we are equipped with various professional processing equipment, and we have accumulated professional processing methods in the past few years.

2/Each component before assembly needs to be strictly controlled by inspectors.

3/After all equipment is completed, we will connect all machines and run the entire production line for at least 12 hours to ensure the stable operation of the customer’s factory.

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier