Welcome to TradeChina

Bi-Oriented Polyvinyl Chloride OPVC PVC-O Pipe Making Machine

FOB Reference Price

Purchase quantity ()

Minimum order quantity

Payment

Jiangsu Faygo Union Machinery Co., Ltd.

China - Suzhou

Manufacturing and trade

Trade Capacity

Export Percentage

70-90%

Nearest Port

Shanghai,Ningbo

Accepted Delivery Terms

FOB,CIF,EXW

Employees

201-300 people

Accepted Payment Currency

USD,EUR,CNY

Average Lead Time

45 Day(s)

Certifications

Product Specifications

--Product Description

Oriented polyvinyl chloride OPVC PVC-O pipe making machine

This PVC-O pipe extruder making machine use newest techology to make plastic pipes. With special biaxial stretching technology, it can largely reduce the material cost for pipe production, more than 50%. It is become more and more popular now days.

Biaxially oriented polyvinyl chloride (PVC-O) pipes are pipes manufactured through a special oriented processing technology. This processing technology is to stretch the PVC-U pipes produced by the extrusion method in axial and radial directions. The long-chain PVC molecules in the pipe are arranged biaxially to obtain a new type of PVC pipe with high strength, high toughness, high impact resistance and fatigue resistance, which is far better than ordinary PVC-U pipes. At present, the strength grade of PVC-O pipe is up to 500, and there are 400 grades and 450 grades. The design coefficients are C=1.6 or 2.0. Among them, the design coefficients of 450 and 500 strength materials can be C=1.4.

Advantages of Oriented polyvinyl chloride PVC-O pipes

1.Anti-corrosion performance, acid and alkali corrosion resistance, also suitable for chemical pipelines.

2.The pressure-bearing performance is greatly improved, and it is more suitable for fire-fighting buried pipelines.

3.High temperature resistance and low temperature resistance are greatly improved.

4.It solves the shortcomings of low strength of HDPE pipes and high brittleness of PVC-U pipe.

5.Become a superior alternative to these two main water supply pipelines.

6.Excellent elasticity and excellent anti-cracking ability. Due to the improvement of the production proce

Advantages of Oriented polyvinyl chloride PVC-O pipes

1.Anti-corrosion performance, acid and alkali corrosion resistance, also suitable for chemical pipelines.

2.The pressure-bearing performance is greatly improved, and it is more suitable for fire-fighting buried pipelines.

3.High temperature resistance and low temperature resistance are greatly improved.

4.It solves the shortcomings of low strength of HDPE pipes and high brittleness of PVC-U pipe.

5.Become a superior alternative to these two main water supply pipelines.

6.Excellent elasticity and excellent anti-cracking ability. Due to the improvement of the production proce

Technical data

| Model/data | Pipe diameter | Extruder model | Speed | Max capacity |

| FP250 | 110-250mm | FGD78 | 1.5-8m/min | 300kg/h |

| FP315 | 160-400mm | FGD93 | 0.5-5m/min | 500kg/h |

| FP630 | 400-630mm | FGD114 | 0.1-2m/min | 800kg/h |

PVC-O pipe is the latest evolutionary form of PVC pipe pipe. By using a special orientation process (biaxial stretching technology), stretching and radial stretching, so that the long-chain PVC molecules in the pipe biaxially arranged in order to obtain high strength, high toughness, high impact resistance, crack resistance of the new PVC pipe.

The stretching orientation process of polymer materials is the process of the molecules arranged from disordered to ordered under the action of external force under the condition of temperature between the glass transition temperature and the melting temperature (usually near the softening point). Biaxial stretching is a process in which a material is biaxially stretched to make the strength perpendicular to the the stretched surface of the biaxial stretching that superimposed on the strength of the stretched surface direction, thereby increasing the strength of the material in the direction of the stretched surface.

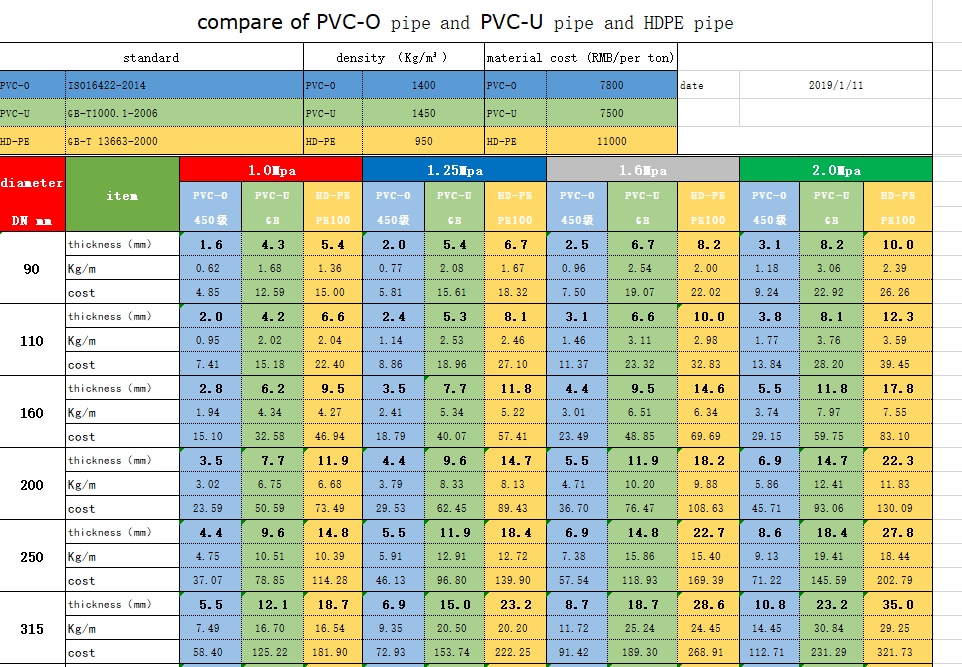

Compare to normal PVC pipes, the pipe wall thickness of OPVC is very thin, but it can endure high pressure. With PVC-O pipe making machine, the client can largely save the material cost.

The stretching orientation process of polymer materials is the process of the molecules arranged from disordered to ordered under the action of external force under the condition of temperature between the glass transition temperature and the melting temperature (usually near the softening point). Biaxial stretching is a process in which a material is biaxially stretched to make the strength perpendicular to the the stretched surface of the biaxial stretching that superimposed on the strength of the stretched surface direction, thereby increasing the strength of the material in the direction of the stretched surface.

Compare to normal PVC pipes, the pipe wall thickness of OPVC is very thin, but it can endure high pressure. With PVC-O pipe making machine, the client can largely save the material cost.

For more details about our PVC pipe making machine, welcome to contact with us. We will reply you in 24hours.

No desirable products?

How to start your business

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier

Supplier's popular products

High Speed PET Blow Molding Machine

$ 75,000

>=1 Set(s)

Faygo Union Automatic Plastic Blowing Machine Water Making 1.5L Plastic Bottle Blowing Machine

$ 75,000 ~ $ 90,000

>=1 Set(s)

Semi Automatic Bottle Blowing Machine Complete Bottle Water Production Line

$ 2,200 ~ $ 2,500

>=1 Piece(s)

3D Pprinter Filament Extruder Machine Lab Single Screw Plastic Extrusion Line with PLC Control

$ 8,500 ~ $ 30,000

>=1 Set(s)

SJSZ-80-156 Twin Screw Extruder Machine for Tpu Double Screw Pvc Pipe Extruder

$ 29,500 ~ $ 31,500

>=1 Piece(s)

High Speed Automatic PET Bottle Blow Molding Machine / Blowing Moulding Machine Price

$ 70,000 ~ $ 75,000

>=1 Set(s)

90~400mm Class 500 PVC-O Pipe Production Line

$ 250,000

>=1 Set(s)

Pe Ps Granulator Foam Product Granulating Plastic Waste Rubber Tyre Recycle Machine

$ 29,000 ~ $ 30,000

>=1 Set(s)

Faygoplast Double Head Aluminium Plastic Composite 3 Layers High Quality Polythene Foam PPR Pipe Machine

$ 30,000

>=1 Set(s)

High Quality Parallel Twin Screw PVC UPVC CPVC Electric Plastic Pipe Machine Line

$ 25,000

>=1 Set(s)

FAYGO UNION Acrylonitrile Butadiene Styrene ABS Plastic Dwv Pipe Line Making Machine Full Automatic

$ 35,000

>=1 Piece(s)

Faygo Union 2024 Twin Screw UPVC PVC Pipe Plastic Extruder Machine

$ 25,000

>=1 Set(s)