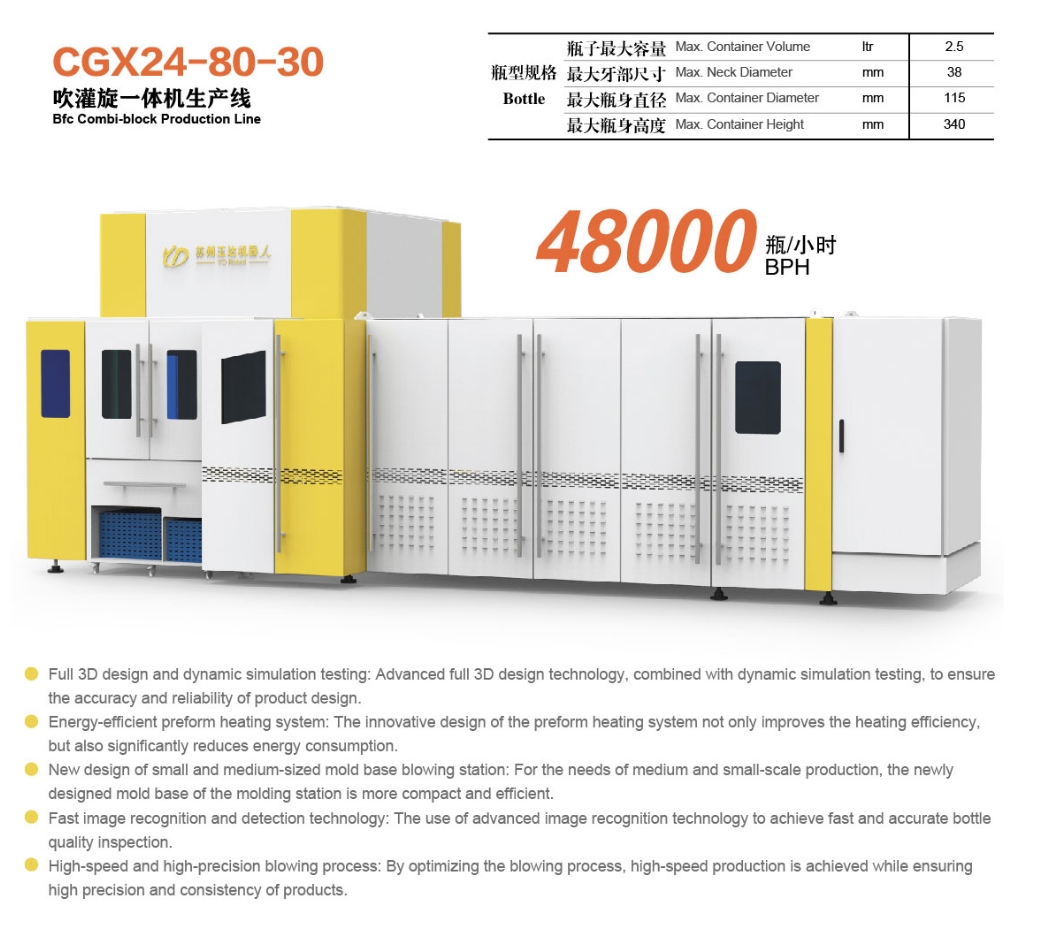

10000~48000BPH Combiblock PET Bottle Water and Beverage Blowing Filling and Capping Machine

Combiblock 10000~48000BPH PET Bottle Mineral Pure Water Beverage Blowing Filling And Capping Machine

This water and beverage plant is a combination of blowing systems, filling systems, and capping systems. It is improved on the basis of the previous filling machine and is directly connected to the blowing machine to avoid bottle wear caused by the empty bottle conveying phenomenon, reduce the weight of the bottle and save costs.

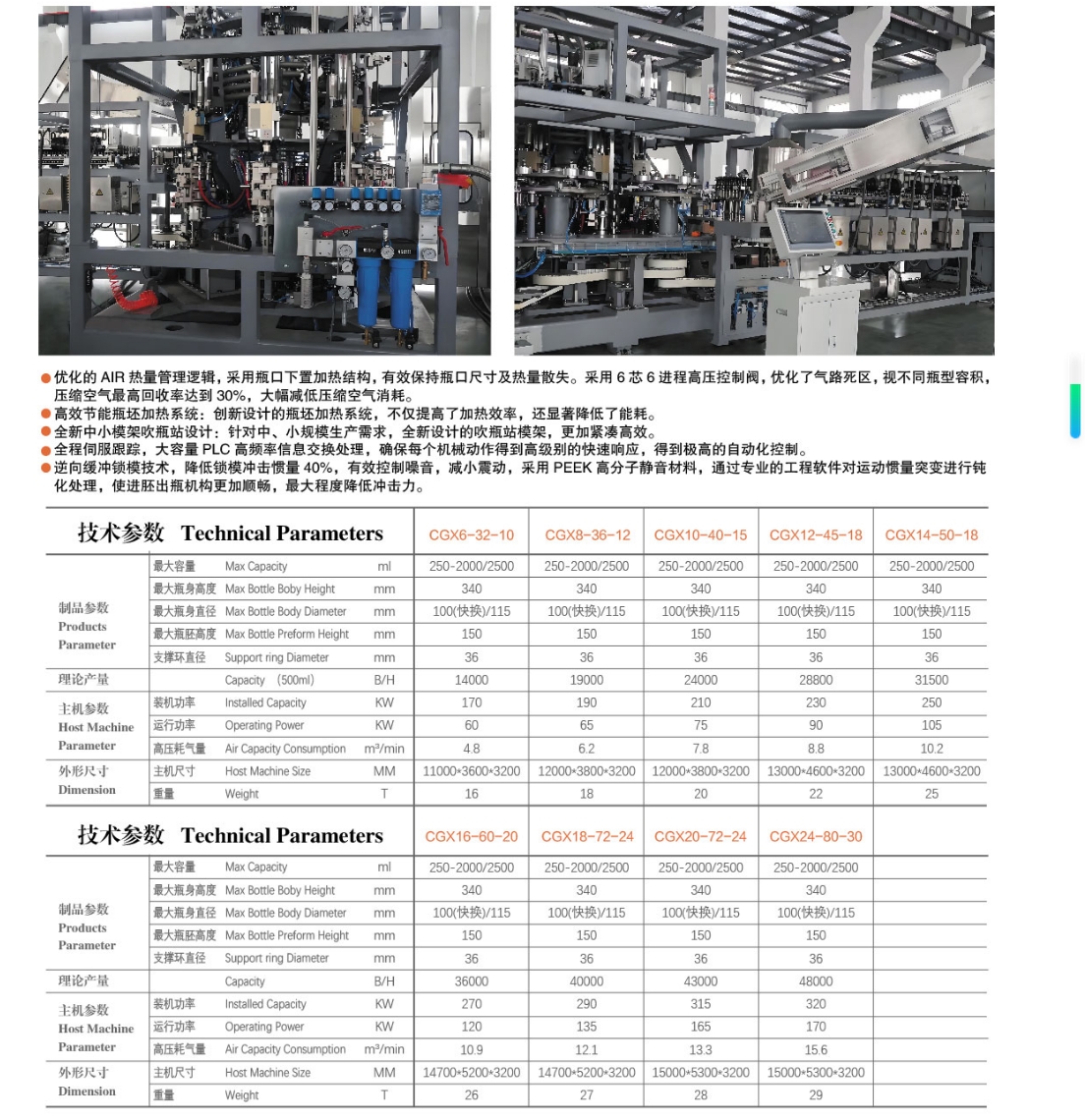

The equipment is suited for carbonated drinks plants, such as the Cola plant, Sprite plant, and Sparkling Drinks plant, ... General Information Of Combi-block CSD Drink 1. This carbonated beverage filling plant consists of an empty bottle blowing part, filling part, capping part, and electrical controlling system. 2. Its standard capacity is 36000BPH for 600ml PET Bottle Screw Cap. (BPH - Bottles Per Hour) 3. This special advantage is with smaller workshop space, higher efficiency production, fewer operators, lower energy consumption, and more reliable quality assurance.

FAYGO UNION GROUP has 3 branch factories. One is FAYGOBLOW which design and make blow molding machine for PET, PE etc. FAYGOBLOW has 5 patents of invention, and 8 patents utility models. FAYGO PET blow molding machine is one of fastest and most energy-efficient design in the world. Second factory is FAYGOPLAST, which make plastic extrusion machinery, including plastic pipe extruding line, plastic profile extruding line. Especially FAYGOPLAST can supply high speed up to 40 m/min PE,PPR pipe line. Third factory is FAYGO RECYCLING, which research new technology in plastic bottle ,film recycling processing and pelletizing. Now FAYGO RECYCLING can make up to 4000kg/hr. PET bottle washing line, and 2000kg/hr plastic film washing line.

Our factory is located in Zhangjiagang city, covers an area of 26,650 square meters. It only takes around two hours driving from SHANGHAI international airport. Welcome to visit our factory, and hope to cooperate with you in the near future.

- Step 1Find your interested products by search keywords

- Step 2Contact the supplier by clicking ”Enquire” or “request meeting” button, otherwise, you also could consult our import consultant.

- Step 3After verifying your email, get response from suppliers or our trade manager will contact you as soon as possible

- Step 4Set up meeting with the Chinese supplier without language barrier